CHALLENGES

At time of initial design, it was known that this location was the site of an old construction landfill, presenting subgrade debris challenges such as concrete and rebar, as well as organic materials within the top 20 feet of compacted fill. Later, it was learned that the pad contractor had used a stabilization technique that had cemented the soils.

Adding to the pre-existing subgrade challenges, down drag on the piles, high lateral loads and a very aggressive construction schedule dictated a sound engineering and project development approach to this Project.

WHAT WE DID

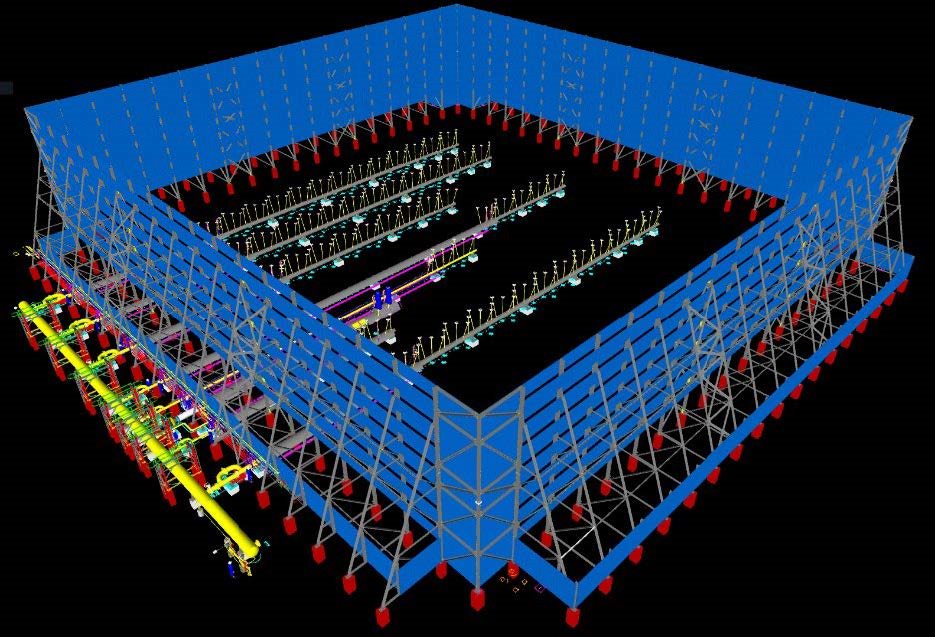

Understanding the need for flexibility in pile placement due to potential for subgrade obstructions and to address the high lateral loads induced by the 60-feet tall radiation fence, TorcSill Engineering designed a concrete pile cap to incorporate a series of medium-diameter helical piles. In addition to overcoming the lateral loading requirements, the pile cap also allowed for pile placement repositioning in the event obstructions were encountered below grade.

Given just four weeks to complete the Project, TorcSill Manufacturing began production of 674 helical piles, sending its first shipment within two weeks of award, and continuing fabrication and shipping throughout the installation process. Five TorcSill Construction Services crews from three of its 13 Operations Districts descended upon the site, completing installation in just two weeks.

SOLUTION

Exercising an in-house Engineering, Manufacturing and Construction Services TEAM approach, TorcSill delivered this Project from concept to as-built to its owner in just 28 days, coming in on schedule and under budget.