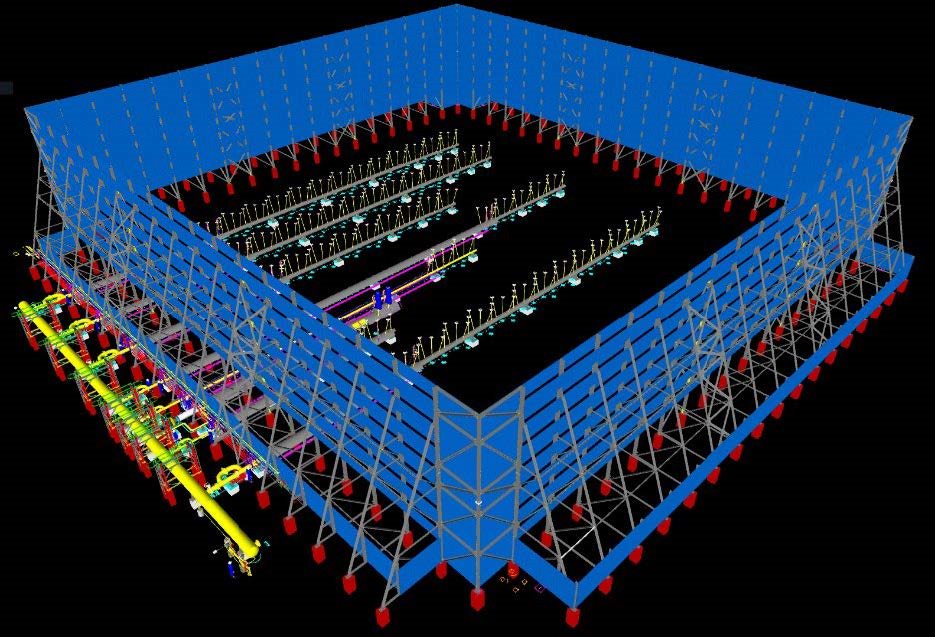

Transformer Containment & Foundation Support

Executive Summary Below is the basic concept of TorcSill’s approach to transformer containment and foundation support: During this project there were 2 Siemens (285k lbs

Our latest work.

Executive Summary Below is the basic concept of TorcSill’s approach to transformer containment and foundation support: During this project there were 2 Siemens (285k lbs

Executive Summary Below is the basic concept of TorcSill’s approach to transformer containment and foundation support: During this project there were 2 Siemens (285k lbs

With incredibly tight clearance between existing underground pipelines and the property boundary, lattice tower foundation construction seemed very difficult. TorcSill designed and installed a helical pile and an all-steel connection detail to allow for ease of installation around buried pipes and without requiring additional property easement.

TorcSill exercised its in-house Engineering and local Operations presence for a quick acting, solutions-focused approach, which proved invaluable for its customer by ensuring no further delays on this foundation replacement Meter Skid Project.

Solving pipeline buoyancy issues through 15 miles of water-inundated marshland in Louisiana. TorcSill was given the opportunity to provide its customer with a fully-integrated and environmentally conscious AnchorPipe solution, solving pipeline buoyancy issues through 15 miles of water-inundated marshland in Louisiana.

Designing and installing 100 piles to support highway integrity in the event of a train derailment along a new track addition. TorcSill worked closely with a major railroad owner and its Engineer of Record on an important public safety Project, successfully designing and installing more than 100 piles to support highway integrity in the event of a train derailment along a new track addition.

Tight construction schedule, zero spoils generation and existing slab foundation remediation. The Coker Unit Foundation Project called into service many of the intrinsic attributes of helical piling foundation design and construction, including tight construction schedule, zero spoils generation and existing slab foundation remediation.

Exhaustive engineering, load testing, custom helical pile manufacturing, installation tooling fabrication. TorcSill’s turnkey solution was the ideal fit for this Project, which required exhaustive engineering, load testing, custom helical pile manufacturing, installation tooling fabrication and one of the largest hydraulic drive motors in the business, all before construction crews were to safely install 30-inch, single-pile foundations.

TorcSill provided helical pile foundation solutions throughout the gas plant, including pipe racks, pipe supports and a wide variety of horizontal and vertical process equipment. Steel-to-steel design for all the foundations were critical in improving schedule, reducing construction complexities and reducing owner’s cost to complete.

Partnering with the owner and its EPCM, TorcSill designed, manufactured and installed more than 23,000 linear feet of helical piling material in less than one month to support a radiation fence for the time-sensitive Ground Flare Project.

TorcSill Foundations is the premier global provider of engineered helical pile and anchor solutions to clients in a broad range of markets. TorcSills (the company’s own brand of helical piles, also known as helical piers and screw piles), are a proven foundation solution ideal for energy, marine, industrial, power, renewable and commercial applications.